Know-how

Problems?

We forge

solutions!

By placing your trust in us, you benefit from proven processes, a diverse range of machinery, our skilled teams, and our specialised know-how in hot stamping and machining of copper and brass.

Your projects,

forged to last

The best possible

mechanical properties

Our hot forging process relieves internal stresses, resulting in a more uniform micro-structure with fewer internal defects and improved mechanical strength and fatigue resistance.

Cost reduction

Compared to material removal processes, our hot forging reduces raw material waste and limits machining to only what is strictly necessary.

The end product

Hot forging enables the creation of complex shapes close to the final design, while our machining processes add the finishing touches to perfectly tailor the part to your requirements.

Time saving

The hot forging process is perfect for medium and large production runs — fast, consistent, and precise.

The art of forging

copper and brass

Non-ferrous metals like copper and brass demand specialised expertise. Every day, we cultivate the art of hot forging these materials with precision, skill, and experience.

The art of forging

copper and brass

Non-ferrous metals like copper and brass demand specialised expertise. Every day, we cultivate the art of hot forging these materials with precision, skill, and experience.

Copper

-

Durable and malleable, ideal for complex shapes

-

Excellent electrical and thermal conductivity

-

Fully recyclable and environmentally friendly

-

Easy to forge, machine, solder, and crimp

Brass

-

High mechanical strength and wear resistance — strong and durable for structural parts

-

Excellent malleability and optimal deformation, enabling hot forging without cracking

-

Good electrical and thermal conductivity

-

Easy to machine and polish

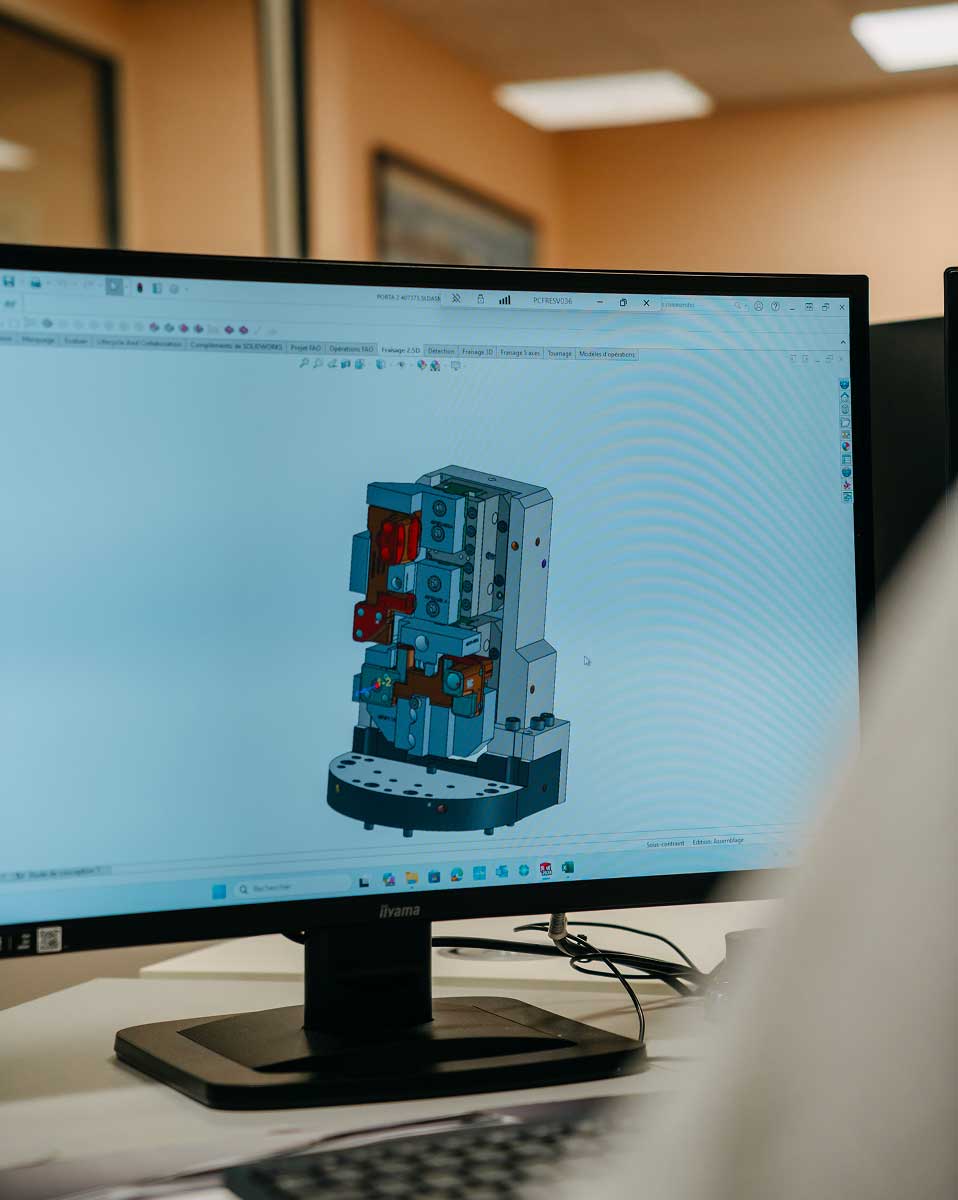

Our production

capabilities

Hot forge

100 to 800-tonne presses for forging billets, cutting machines for burr removal, and saws to cut copper bars into billets.

Surface treatment

Acid pickling line, stripping and tribofinishing area, and a “Zero Waste” effluent treatment station.

TAILORED SOLUTIONS

FOR YOUR PROJECTS

We offer support and a customised approach for each of your projects.

This includes the following steps:

They trust us

Would you like to know more?

Connect with our experts today and bring your hot forging project to life. Don’t miss the opportunity to forge excellence with us!